Key factors affecting the service life of air compressor

Product design

Manufacturing and assembly

Installation and commissioning

Maintenance

It is very important to install the air compressor correctly. Improper installation will cause failure of air compressor to work normally, seriously affecting its service life and incurring additional maintenance and repair costs.

Main considerations for installation

Installation environment of air compressor

Installation layout of air compressor

Pipeline connection of air compressor

Air compressor ventilation and duct installation

Air compressor ventilation and duct installation

Installation of air compressor power supply line

Good ventilation

Ambient temperature of 0-45 °C

Away from dust

No harmful gas

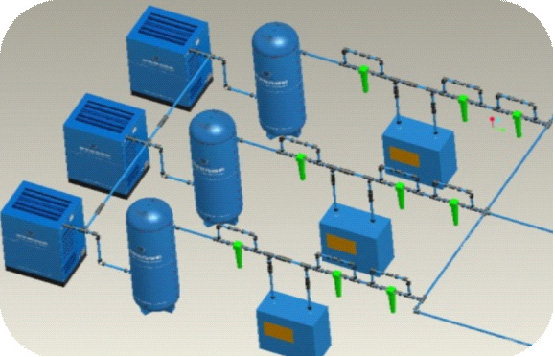

Installation layout of unit and air handling equipment

- Air compressor

- Air storage tank

- Primary filter

- Refrigerated air dryer

- Medium / high-efficiency filter

Important note: The distance between air compressor and wall or other equipment shall be greater than 1.5 m!

Installation layout of unit and air handling equipment

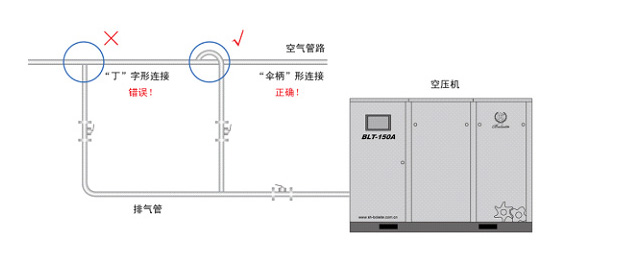

The pipe diameter shall be not smaller than the diameter of air compressor outlet.

No T-shaped installation of branch pipe and main pipe is allowed.

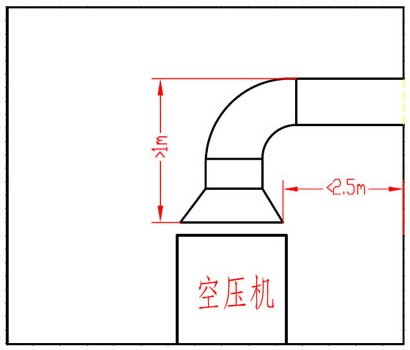

Installation of ventilation duct

The ventilation duct of air compressor shall be designed according to the requirements in the instructions to avoid reducing!

Requirements of cooling water system

Selecting water pump

>> Sufficient flow and lift

Water quality

>>Tests and corresponding water treatment measures are required.

-pH value: 6.8<pH< 8; water temperature: 0 - 35 °C

-Water pressure: 3.0-5.5bar; pressure difference between inlet and outlet water: > 1.5 bar

>>Avoid deep phreatic water and chilled water

Water supply flow

>>Q=[KW/(4.2x∆T )]x3.6 t/h (∆T=8°C)

Inlet pipe

>>A filter screen (30-40 meshes / cm2) shall be installed.

>>A blowdown valve shall be installed at the end.

Power supply installation requirements

- Air compressor power supply line inlet

- Inlet box required to be installed

- Incoming cable with a certain radian

Voltage requirements

>> Three-phase 380 V±5%, voltage fluctuation

>>1% unbalance of three-phase voltage

>>Allowable frequency of 50 HZ ±1%(0.99~1.01)

Grounding requirements

>> Null line (N) and protective earth (PE) grounded separately or together

Startup and commissioning of air compressor

Startup and commissioning are essential for the stable operation of the unit in the future. They are closely related to the normal use, maintenance cost and service life of the unit. Therefore, the startup and commissioning must be completed by Bolaite or any authorized service agent of Bolaite. No one who has not received professional training, other than our service personnel, is allowed to complete startup and commissioning.