Precautions before use

l The air compressor cannot be used until the factory service personnel arrive at the site to start the machine for commissioning and the result is normal

l Please read the operation instruction of air compressor carefully before use

l Arrange special personnel to use and manage the air compressor

l Record the operation data of the unit

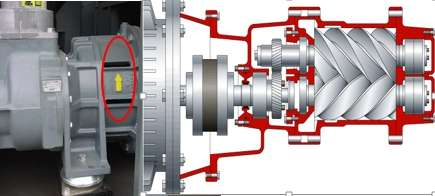

In use - Forbidden reverse rotation of the rotor

Reverse rotation will lead to great loss of rotor from being seized and scrapped

Correct direction of rotor rotation →

The direction of rotor rotation must be reconfirmed under the following conditions

lStart-up and commissioning of machine

lRemoval and relocation of the power wire

lReplacement of the contactor

lCommutation of power transformer

Prevention of accumulated water in lubricating oil

lAccumulated water in the oil line will bring great losses to the unit

lIf the severity is light, all the consumables of the oil line system will be damaged

lOtherwise, the rotor gearbox will be scrapped

Rotor after water accumulation ↓

特别注意下列几种情况

lDuring factory trial production stage; under high atmospheric humidity, e.g. low loading rate of units in plum rains season in Jiangnan area

lIn case of low exhaust temperature, corresponding measures shall be taken immediately to frequently check the oil level to see if there is abnormal rise

lBefore each start-up, drain a little lubricating oil from the oil drain pipe at the bottom of the oil-gas cylinder; try to increase the exhaust temperature (adjust the fan temperature switch, etc.)

Before each start-up, drain a little lubricating oil from the oil drain pipe at the bottom of the oil-gas cylinder; try to increase the exhaust temperature (adjust the fan temperature switch, etc.)

Check the wiring of the main circuit regularly; check the upper and lower pile heads of the contactor; is the motor binding post is loose or heated?

Prevention of frequent start-up and shutdown of the unit

lThe start-stop cycle shall preferably be over 1-2 hours

lAvoid frequent loading and unloading of the unit, and the loading and unloading period shall preferably be over 5-10 minutes

lAvoid air leakage of the unit

Attention to the quality of power supply

lThree-phase voltage fluctuation is allowed to be 380±5% V, which is 400 V/360 V

lVoltage imbalance of 1% causes a certain phase current to exceed 10%

lVoltage imbalance of 3% increases the temperature rise of motor by 25°C.

lAllowable frequency range: 50HZ±1% (0.99-1.01)

Regular check on the following items

lAll protection devices are installed in place and fixed; all hoses and (or) pipes in the machine are in good condition, safe and free from wear and leakage;

lAll fasteners are tightened; all electrical leads are safe and orderly;

lSafety valves and other pressure relief devices are not blocked by dirt or coating;

lThe air outlet valve and air pipe network (i.e., pipes, couplings, manifolds, valves, hoses, etc.) are well maintained without wear or abuse;

lIf the hot air exhausted from the air compressor is used in the air heating system (e.g. to warm the working chamber), please take precautions to prevent the breathing air from being polluted;

lDo not disassemble or tamper with any sound insulation materials; do not disassemble or tamper with the safety devices, protection devices or insulators installed on the machine;

lOne or more pressure relief devices shall be used as required to protect each pressure vessel or auxiliary equipment installed outside the machine with air above atmospheric pressure.